-

The factory

-

Entrance

-

Tooling area

-

Tooling area

-

Tooling area

-

Tooling area

-

Offices

-

Offices

-

The warehouse from outside

-

Warehouse

-

Warehouse

-

Warehouse

-

Receiving area

-

Receiving area

-

Entry to the moulding area

-

Entry to the quality control area

-

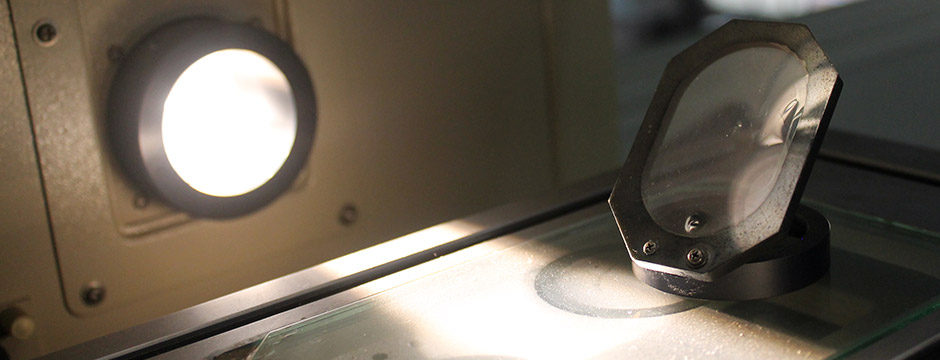

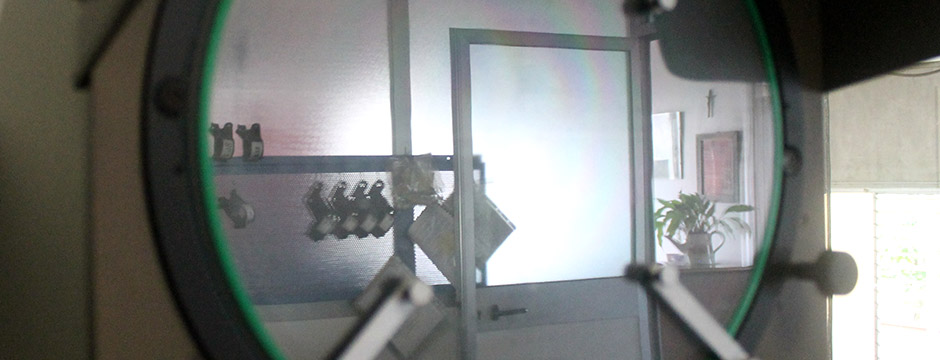

Quality control

-

Quality control

-

Quality control